| |

Would someone care to tell me how to take the slack out of wormgear joints? I

love their strenth but hate the wobble. Anything you can give me would be

appreciated. Thanks.

-Brayton

|

|

| |

In lugnet.build.mecha, Brayton Orchard wrote:

| |

Would someone care to tell me how to take the slack out of wormgear joints? I

love their strenth but hate the wobble. Anything you can give me would be

appreciated. Thanks.

-Brayton

|

The backlash (spacing between the teeth of a gear and the splines on the worm

gear) is difficult to over come.

There are some techniques to reduce the effect.

1. Use Technic Throwbot Gear Boxes and use a z40 in the set up.

2. Use a compund system. Worm Gear to z24, axle, z8 to z40 then bind the beam

to the z40 with Technic half axle pins.

3. Use levers and shock absorbers to act as tendons and muscles that suround

the gear set up.

4. Use a premade worm box.

The worm gears have a small amount of slack (different from backlash) so the

gear can rotate freely on an axle between bushings.

The backlash present in the worm gears translates to a wobble in the Mech’s

joints. I counter this by torquing the limbs, say, the legs, against eachother.

Meaning, if one leg is forward, and the other leg is pitched back, slowly adjust

the gears (tune or turn the drive axle) until you feel the weight begin to

shift. Counter the Mech’s weight by turning the opposite leg’s worm gear until

it begins to push the weight of the Mech. At this point the Mech will begin to

balance and you will feel the tension of the opposite leg.

So using the limbs themselves to counter the backlash against eachother, is

another technique.

Hope that helps.

e

|

|

| |

Thanks a lot Eric. That’ll do just fine.

-Brayton

|

|

| |

Hi Brayton,

While erics reply is pretty comprehensive, have you posted to .technic

to see what they have there?

Warning - I am about to databurst again...

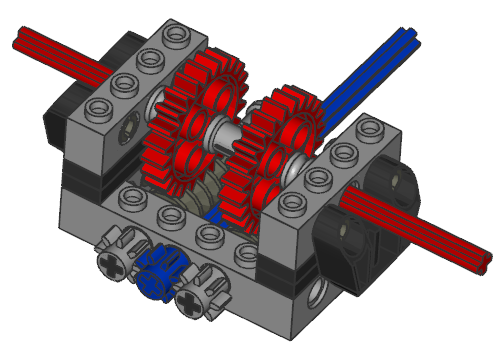

I can see what eric says about the counter system - and I wander if if

could be simply overcome by having a set of two worm gears meshing

with a set of two 40t gears on the same axle - you can have the worm

gear axles linked so you can do the large adjustment together, and

then take advantage of the backlash of the gears in the system

connecting the two worms to turn them slightly against each other to

oppose the backlash on their link with the 40t's. This would then mean

it could be used without having to take it into account as part of the

balancing of the creation.

To try and save peoples brains from bursting - I went and had some fun

with MLCad and LPub:

To download the mpd file:

http://orionrobots.co.uk/tiki-download_file.php?fileId=27

To view the rendered output:

http://orionrobots.co.uk/tiki-browse_image.php?imageId=351

Cheers,

Danny

--

Danny Staple MBCS

OrionRobots

http://orionrobots.co.uk

(Full contact details available through website)

On 21/12/05, Brayton Orchard <braytono@hotmail.com> wrote:

> Would someone care to tell me how to take the slack out of wormgear joints? I

> love their strenth but hate the wobble. Anything you can give me would be

> appreciated. Thanks.

>

> -Brayton

>

|

|

| |

> Warning - I am about to databurst again...

> I can see what eric says about the counter system - and I wander if if

> could be simply overcome by having a set of two worm gears meshing

> with a set of two 40t gears on the same axle - you can have the worm

> gear axles linked so you can do the large adjustment together, and

> then take advantage of the backlash of the gears in the system

> connecting the two worms to turn them slightly against each other to

> oppose the backlash on their link with the 40t's. This would then mean

> it could be used without having to take it into account as part of the

> balancing of the creation.

>

> To try and save peoples brains from bursting - I went and had some fun

> with MLCad and LPub:

>

> To download the mpd file:

> http://orionrobots.co.uk/tiki-download_file.php?fileId=27

>

> To view the rendered output:

> http://orionrobots.co.uk/tiki-browse_image.php?imageId=351

>

> Cheers,

> Danny

> --

> Danny Staple MBCS

> OrionRobots

> http://orionrobots.co.uk

> (Full contact details available through website)

I've done a similar solution however:

I put 2 worm gears on 1 40t gear. One on top and one on the bottom. My intent

was to counter the slipping that happens under severe loads. Though it's a pain

to turn (you have to turn 2 axles in opposite directions) it works well.

That said you can do the same function as your idea above by turning one and not

the other.

|

|

| |

Hey Danny, thats interesting. You may be on to something.

I'm wondering, when a corrective tension is added (turning the opposing gear)

the center of the axle will twist.

Also, because the two drives are linked with z16's, when you turn one, the other

is just going to turn as well, negating the tension effect.

Some how a derivative of this set up would be the answer.

One other peice of info.

When you said, add two worms together, I thought you ment (until I saw your

render) add two worm gears to a single axle. To make them double long.

I learned that there are two types of worm gears. The older and newer style.

The older style has an axle grab the whole way through the gear. Meaning you can

see the axle accept on both sides. Front to back.

The newer style worm gears only have an axle grab part of the way through, and a

hollow end at one side.

The advantage of the older style is that you can put two on a single axle and

the splines mate up almost seamlessly. To make the worm gear double long.

The newer style worms have more of a blunt end on the splines and when you add

them two of them to an axle, they do not mate up as smoothly as the older ones.

Take a look and compare. See if you have both the older ones and new ones.

Then add them to a long axle and see how the ends mate up either smoothly or

with a small bump of hicup at the point where they meet on the axle.

The older ones have a finer/thinner end spline.

e

P.S. I don't know if Peeron has this difference listed.

Old and new style worm gears.

|

|

| |

On 22/12/05, Eric Sophie <mylegomaster@aol.com> wrote:

> Hey Danny, thats interesting. You may be on to something.

> I'm wondering, when a corrective tension is added (turning the opposing gear)

> the center of the axle will twist.

>

> Also, because the two drives are linked with z16's, when you turn one, the

> other

> is just going to turn as well, negating the tension effect.

>

> Some how a derivative of this set up would be the answer.

>

> One other peice of info.

>

> When you said, add two worms together, I thought you ment (until I saw your

> render) add two worm gears to a single axle. To make them double long.

>

> I learned that there are two types of worm gears. The older and newer style.

>

> The older style has an axle grab the whole way through the gear. Meaning you

> can

> see the axle accept on both sides. Front to back.

>

> The newer style worm gears only have an axle grab part of the way through, and

> a

> hollow end at one side.

>

> The advantage of the older style is that you can put two on a single axle and

> the splines mate up almost seamlessly. To make the worm gear double long.

>

> The newer style worms have more of a blunt end on the splines and when you add

> them two of them to an axle, they do not mate up as smoothly as the older

> ones.

>

> Take a look and compare. See if you have both the older ones and new ones.

> Then add them to a long axle and see how the ends mate up either smoothly or

> with a small bump of hicup at the point where they meet on the axle.

>

> The older ones have a finer/thinner end spline.

>

> e

>

> P.S. I don't know if Peeron has this difference listed.

>

> Old and new style worm gears.

Hi Eric,

I actually intended that the inherent backlash in the z16s was

exploited to turn them in a little after the positioning. You could

replace my z16s with two z24s and a z8, making one of the z24s a

clutch gear so you could turn them against each other. Either way -

you can do the positioning by just turning one of the gears - which

saves the hassle which bryce described.

Hmm - I didnt actually know about or spot this difference, but I

probably have some of each of those gears. My big worry about the new

worm gears is that they will be able to deal with much less torque of

stress than the older ones - which in this case could be a really

serious problem. I will take a good look at them now!

Danny

--

Danny Staple MBCS

OrionRobots

http://orionrobots.co.uk

(Full contact details available through website)

|

|

| |

In lugnet.build.mecha, danny staple orionrobots@gmail.com wrote:

| |

Hi Eric,

I actually intended that the inherent backlash in the z16s was

exploited to turn them in a little after the positioning. You could

replace my z16s with two z24s and a z8, making one of the z24s a

clutch gear so you could turn them against each other. Either way -

you can do the positioning by just turning one of the gears - which

saves the hassle which bryce described.

|

A very interesting trick, Danny. Here is my implementation of your no-backlash

transmission:

Of course there is a trade-off between backlash and friction, but your design

allows easy trimming.

Philo

|

|

| |

In lugnet.build.mecha, Eric Sophie wrote:

| |

SNIP

I learned that there are two types of worm gears. The older and newer style.

The older style has an axle grab the whole way through the gear. Meaning you

can see the axle accept on both sides. Front to back.

The newer style worm gears only have an axle grab part of the way through, and

a hollow end at one side.

The advantage of the older style is that you can put two on a single axle and

the splines mate up almost seamlessly. To make the worm gear double long.

The newer style worms have more of a blunt end on the splines and when you add

them two of them to an axle, they do not mate up as smoothly as the older

ones.

|

The new style worm gears have the advantage, that they can be put onto a

5.5- axle like shown in the following pics.

No additional parts are needed to fix the axle inside the gear!!

Thanks for pointing out, there are two types of worm gears. I never

realized there were. But when I knew there was this idea.

Marco

|

|

|