Subject:

|

The NUT of the day : One Stud Offset

|

Newsgroups:

|

lugnet.build.schleim

|

Date:

|

Tue, 30 Jun 2009 20:54:27 GMT

|

Highlighted:

|

!!

(details)

|

Viewed:

|

31473 times

|

| |

|

|

ABT (Advanced Building Techniques) are widely used. Everyone knows for instance

the use of a jumper plate to achieve a half stud offset (AZMEP)

Another one consist in stacking 1xn parts on hollow stud in a tube to hollow

stud connection.

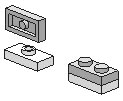

The jumper plate IS a hollow stud part. What if we combine these two techniques?

You achieve an incredible one-stud offsetand get great advantages :

- only two plates thick,

- less clutch power for immediate disassembling

- limited jumper plate colour availability for increased building challenge

and the most amazing is that this technique has

- No SNOT side effects.

To conclude I encourage you to share your favorite NUTs (New Useless Technique)

in reply to this post

Schleim well,

Didier

|

|

Message has 3 Replies:

| | Re: The NUT of the day : One Stud Offset

|

| (...) All humor aside, this is actually a useful technique...in one specific instance (well, probably two, now). When you put a grille tile down on a regular plate, the studs fill in the gaps nearly completely. When you put a grille tile down on a (...) (17 years ago, 1-Jul-09, to lugnet.build.schleim, FTX)

|  | | Re: The NUT of the day : One Stud Offset

|

| (...) Which contradicts your claim of uselessness for the following reasons: less clutch power is sometimes desirable - I have used this exact construction in a GBC module to allow easy removal of a part for maintenance. The clutch is even less than (...) (17 years ago, 1-Jul-09, to lugnet.build.schleim, FTX)

|

4 Messages in This Thread:

- Entire Thread on One Page:

- Nested:

All | Brief | Compact | Dots

Linear:

All | Brief | Compact

|

|

|

|